Whereas in today’s interconnected and fast paced world, a Supply Chain is more than just logistical backbones they are strategic assets. Because for too long. Therefore the goal of supply chain design was stability. Hence to void disruption. Maintain control. Keep things predictable. But the world has changed, and with it, so must our approach.

Supply Chain Thinking: Turning Uncertainty Into Competitive Advantage

The real leap forward in state of thinking isn’t just about resisting shocks. Therefore it’s about adapting so quickly to volatility that uncertainty itself becomes a lever for advantage, rather than a cause for concern.

What Is a Supply Chain?

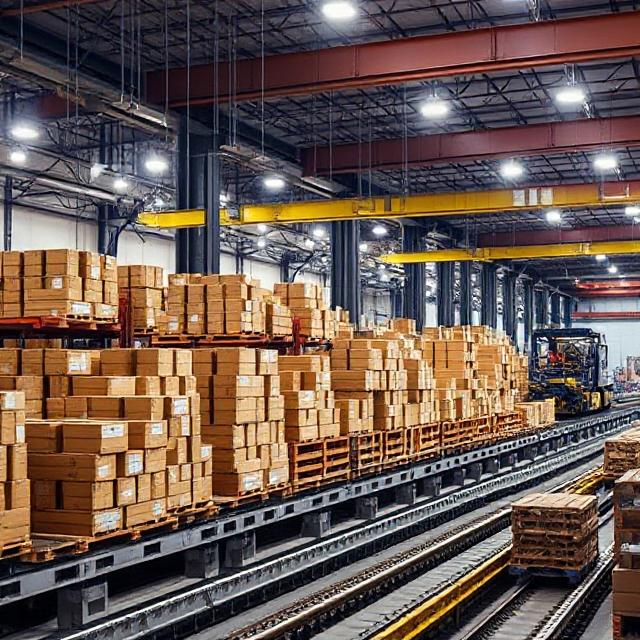

At its core, it is a complex logistics system. Therefore a network of facilities that convert raw materials into finished products and distribute them to end consumers. Because these facilities span factories, warehouses, transportation hubs, and retail networks. Therefore each node plays a vital role in turning raw potential into real value.

Supply chain management (SCM) focuses on the efficient movement of goods across this network. Therefore coordinating production, inventory, and transportation to ensure the right products are delivered. Hence at the right time, at the right cost.

Whereas modern SCM doesn’t stop at delivery. In sophisticated supply chain systems. Therefore used products can re enter the chain through processes like remanufacturing, recycling, or reverse logistics. Hence extracting residual value and further enhancing sustainability.

Managing the Supply Chain Uncertainty

Therefore traditional services were built on the assumption of predictability. But global events. Therefore from pandemics to political unrest to climate related disasters. Whereas have revealed just how fragile that assumption can be.

Therefore this brings us to the concept of supply chain uncertainty management. Thereby which can be viewed as a spectrum of organizational response:

Fragile State

Whereas in a fragile state, uncertainty leads to loss financially, operationally, and reputationally. Because these systems are brittle, overly optimized for efficiency, and ill equipped for surprise. Therefore when the unexpected strikes, fragile chains break.

Resilient State

Whereas resilient supply chains can absorb shocks. They don’t gain from uncertainty, but they don’t lose either. Therefore they bend, but don’t break. Hence this is the current gold standard for many organizations. Therefore designing systems that withstand disruptions without significant damage.

Antifragile State

Hence the antifragile state does something remarkable: they get stronger from stressors. Therefore like biological immune systems or decentralized tech networks. Because these systems use disruption as a signal to improve. Thereby volatility becomes a source of learning, adaptation, and advantage.

“Antifragility isn’t about survival—it’s about evolution.“

Supply Chain Reactive to Proactive

Making the leap from fragility to antifragility requires a mindset shift:

-

From prediction to preparedness.

-

Hence from efficiency to adaptability.

-

From static plans to dynamic learning.

This doesn’t mean throwing away operational discipline. It means building intelligent flexibility into the system. Therefore leveraging real time data, agile decision making, and ecosystem wide visibility.

How to Build an Antifragile Supply Chain

-

Design for Optionality

Redundancy isn’t waste it’s insurance. Multiple sourcing options, modular production, and flexible transport routes provide optionality in the face of disruption. -

Enable Rapid Feedback Loops

Sensors, analytics, and AI enable faster detection and response. Organizations must invest in digital supply chain infrastructure that translates data into action. -

Encourage Decentralized Decision Making

Localized teams should be empowered to make decisions in real-time. Centralized bottlenecks slow response and amplify fragility. -

Collaborate Across the Ecosystem

Suppliers, logistics partners, and customers are not just links in the chain, they’re nodes in a network. Transparency and trust across this network are key to dynamic adaptation. -

Learn from Disruption

Every shock is an opportunity to understand system weaknesses and improve. Build processes to review, learn, and embed resilience with each event.

Supply Chain Thinking

We’re entering an era where speed of adaptation trumps static planning. The organizations that thrive won’t be the ones that merely survive the next crisis, but those that evolve from it. Read our Web Design Okc Blog for great information on this subject and more.

Uncertainty is no longer a temporary condition, it’s the default. And in that reality, the Supply Chain Thinking becomes not just a cost center or a service function, but a strategic weapon.

In a fragile world, antifragility is the ultimate advantage.

Want to assess where your supply chain stands on the fragility resilience antifragility spectrum?

Contact us today for a diagnostic consultation.